Tool building of SKS Kontakttechnik GmbH -

Technical / technological competence within our company

The strength of tool building from SKS Kontakttechnik GmbH is that all technologies are available that are necessary for a modern tool and mould making.

Our qualified experts contributes together with developing department and pre-fabrication to implement technical and technological know-how of SKS Kontakttechnik GmbH.

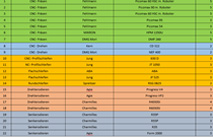

Currently designed, produced, tested and brought to series production will be among other things:

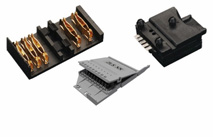

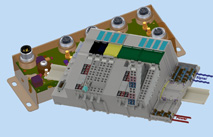

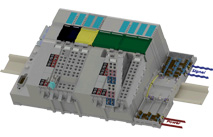

- Injection moulding tools with changing and modular systems for several products

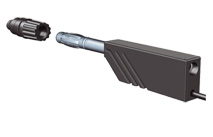

- Overmoulding tools with different metal and plastic elements

- Multi-component mould tools

- Injection moulding tools for products with an high glass fibre content

- Injection moulding tools for optical parts

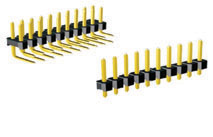

- Progressive high-precision tools for smallest electrotechnical components

- Contact punching tools

Technologies of tool building

- Tool construction CAD-CAM (solidworks)

- CNC milling, HSC/ HPC, graphite milling, 3 and 5-axis milling

- CNC cylindrical, flat and profile grinding

- CNC turning, cycle-by-cycle

- Wire erosion, Twin Wire, up to 0,1

- Start hole boring

- Die-sinking, smallest cavities

- Laser deposition welding

- Electrodes and coordinate measuring machine (3D)